Description

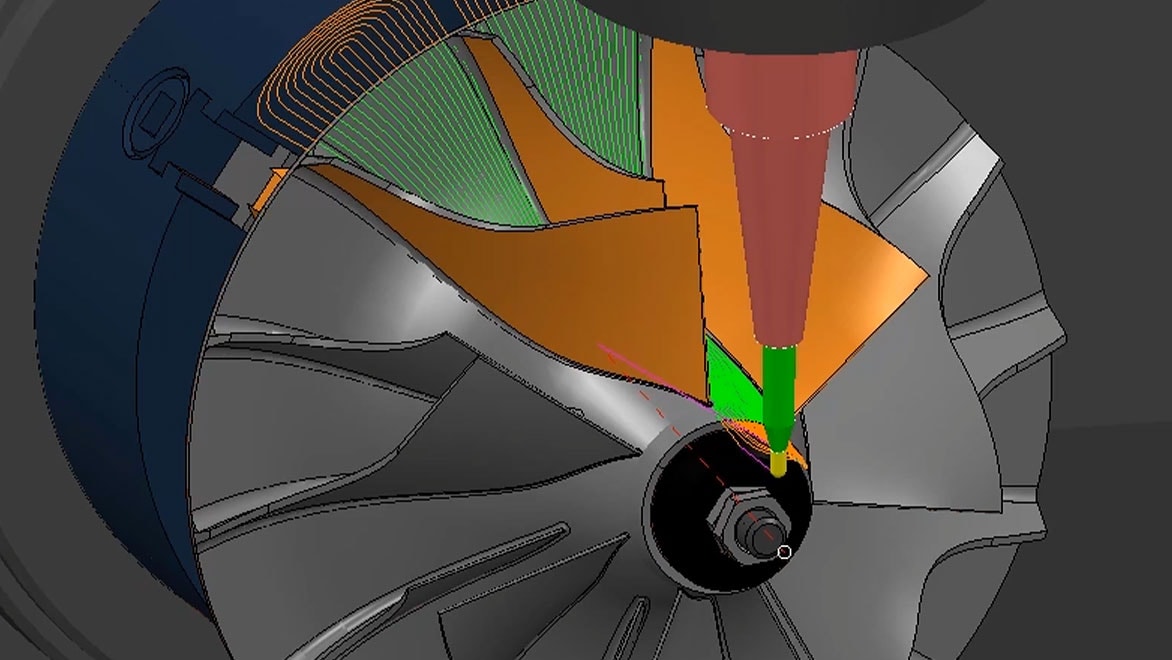

Autodesk PowerMill Ultimate 2024 Lifetime Activation for Windows

Lifetime Activation

You will receive the software to install.

We will activate the software for you by TeamViewer

CNC machining has revolutionized the manufacturing industry, enabling the production of highly intricate and precise components. To achieve such precision and efficiency, manufacturers rely on advanced CAM (Computer-Aided Manufacturing) software like Autodesk PowerMill Ultimate. In this article, we will delve into the world of PowerMill Ultimate, exploring its robust features that empower manufacturers to turn their machining dreams into reality.

Section 1: Toolpath Generation One of the core features of PowerMill Ultimate is its exceptional toolpath generation capabilities. Users can:

- Generate 2D and 3D toolpaths effortlessly.

- Optimize toolpaths for efficiency and surface finish.

- Implement advanced strategies for complex geometries.

- Minimize tool wear and extend tool life through intelligent path planning.

Section 2: Toolpath Simulation and Verification PowerMill Ultimate ensures precision through simulation and verification:

- Realistic simulation of machining processes.

- Collision detection to prevent costly errors.

- Material removal simulation for accuracy assessment.

- Verification of multi-axis toolpaths.

Section 3: 5-Axis Machining PowerMill Ultimate’s 5-axis machining features:

- Enables the machining of intricate shapes and undercuts.

- Smooth and continuous toolpath generation.

- Enhanced surface finish and reduced cycle times.

- Support for multi-axis CNC machines.

Section 4: Adaptive Clearing Efficient material removal is vital, and PowerMill Ultimate offers Adaptive Clearing:

- High-speed machining with minimal tool load.

- Improved surface finish and reduced machining time.

- Adaptive toolpaths that adjust to varying conditions.

Section 5: Collision Detection and Avoidance PowerMill Ultimate’s collision management:

- Identifies potential collisions during toolpath planning.

- Suggests alternative paths to avoid collisions.

- Ensures safe and error-free machining.

Section 6: High-Speed Machining (HSM) HSM in PowerMill Ultimate:

- Optimizes toolpaths for high-speed milling.

- Reduces machining time while maintaining accuracy.

- Minimizes tool wear for extended tool life.

Section 7: Robot Machining (if applicable) For robotic machining applications:

- Seamlessly integrates with robotic arms.

- Creates robot-specific toolpaths.

- Expands the scope of automated machining.

Section 8: Additive Manufacturing (if applicable) For additive manufacturing processes:

- Supports a range of 3D printing and additive technologies.

- Generates optimized toolpaths for layer-by-layer deposition.

- Enables hybrid machining combining additive and subtractive methods.

Section 9: User Interface and Workflow PowerMill Ultimate boasts a user-friendly interface and efficient workflow:

- Intuitive navigation and customizable interface.

- Streamlined toolpath creation and editing.

- Integration with other Autodesk software products.

Section 10: Benefits and Advantages The benefits of choosing PowerMill Ultimate include:

- Precision machining for complex geometries.

- Reduced machining time and increased productivity.

- Lower tooling costs and material waste.

- Enhanced competitiveness in manufacturing.

Section 11: Integration and Compatibility PowerMill Ultimate seamlessly integrates with:

- Other Autodesk software products like Fusion 360 and Inventor.

- A wide range of CNC machines and controllers.

- Third-party hardware and software solutions.

Section 12: Training and Support Autodesk provides extensive training and support resources:

- Online tutorials, documentation, and webinars.

- Active user community and forums.

- Responsive customer support for technical assistance.

Section 13: Real-World Applications Explore real-world applications where PowerMill Ultimate excels:

- Aerospace component manufacturing.

- Mold and die production.

- Automotive part machining.

- Medical device fabrication.

Autodesk PowerMill Ultimate stands as a powerhouse in CNC machining software, offering a rich set of features that cater to the most demanding machining tasks. Its precision, efficiency, and versatility make it an indispensable tool for modern manufacturers seeking to push the boundaries of what’s possible in CNC machining.